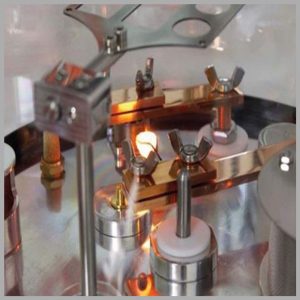

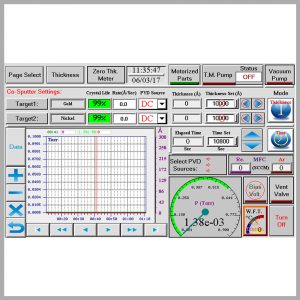

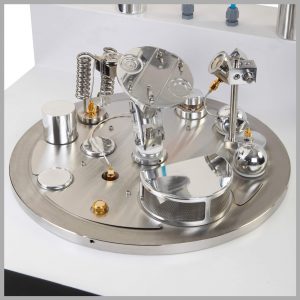

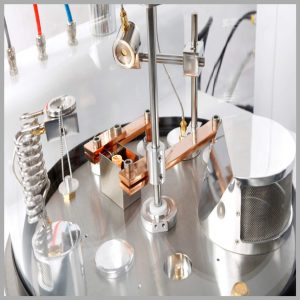

The DST3-T, Triple Target Turbo Pumped Sputter Coater, is a multi vacuum coater system that combines thermal evaporator and sputter coater in one single compact desktop system. The high vacuum system is suitable for deposition of a wide range of materials. Triple magnetron target desk sputter coater can easily switch between Evaporation and Sputtering condition (Not Simultaneously).

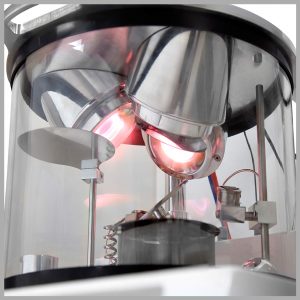

The DST3-T, Magnetron Desk Sputter Coater, is equipped with a large chamber (300 mm diameter) and three 2” diameter water-cooled cathodes which make it suitable for long time deposition. The magnetron desk sputter coater is equipped with RF and DC power supplies. It can sputter semiconductors, dielectrics and metal (oxidizing & noble) targets.

The sputter coater system is equipped with an auto adjustable matching box, minimizing the reflected power in the RF sputtering process. For increasing film adhesion to the substrate and to improve the film structures, a 300 V, DC bias voltage can be applied to the substrate (optional).